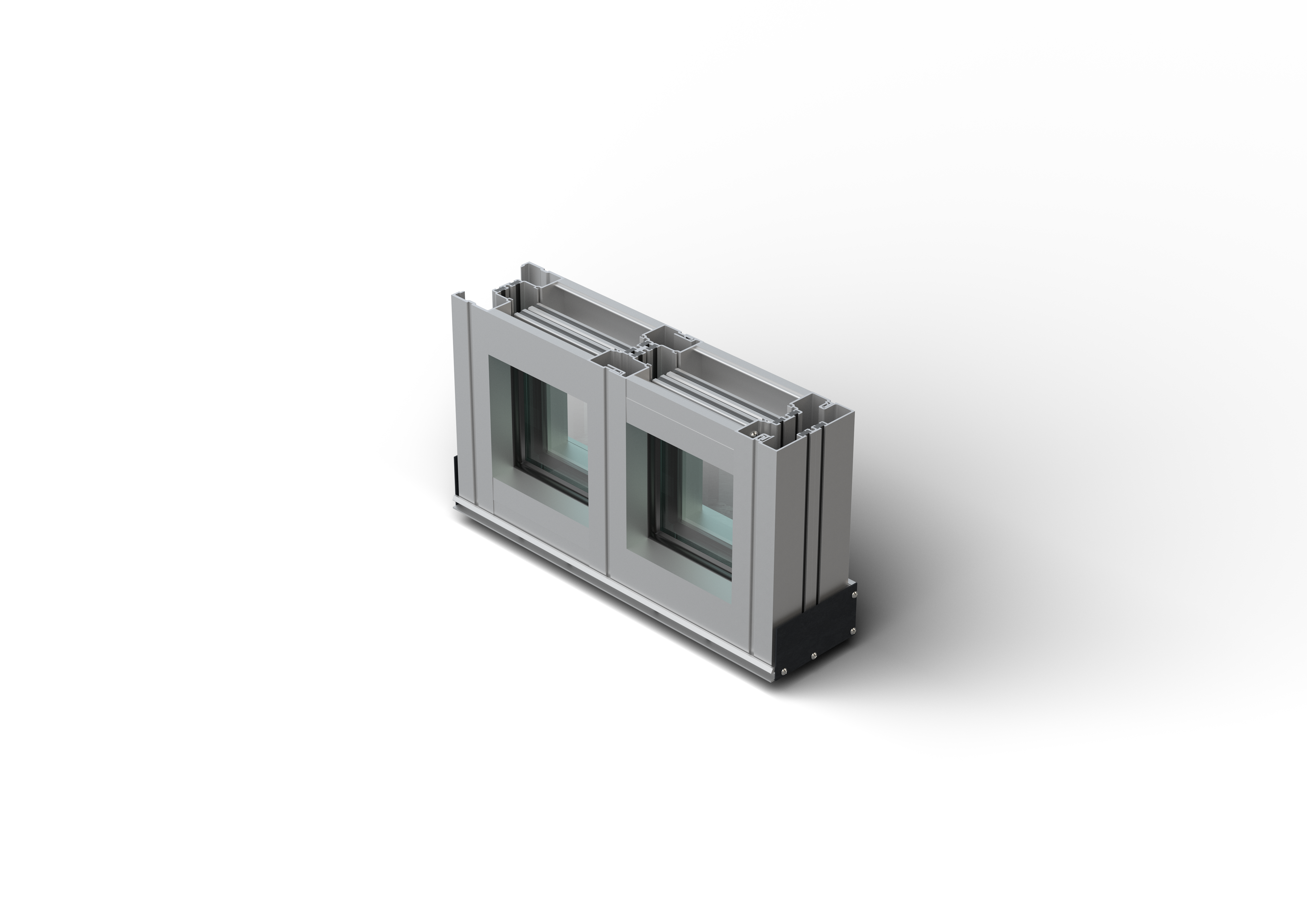

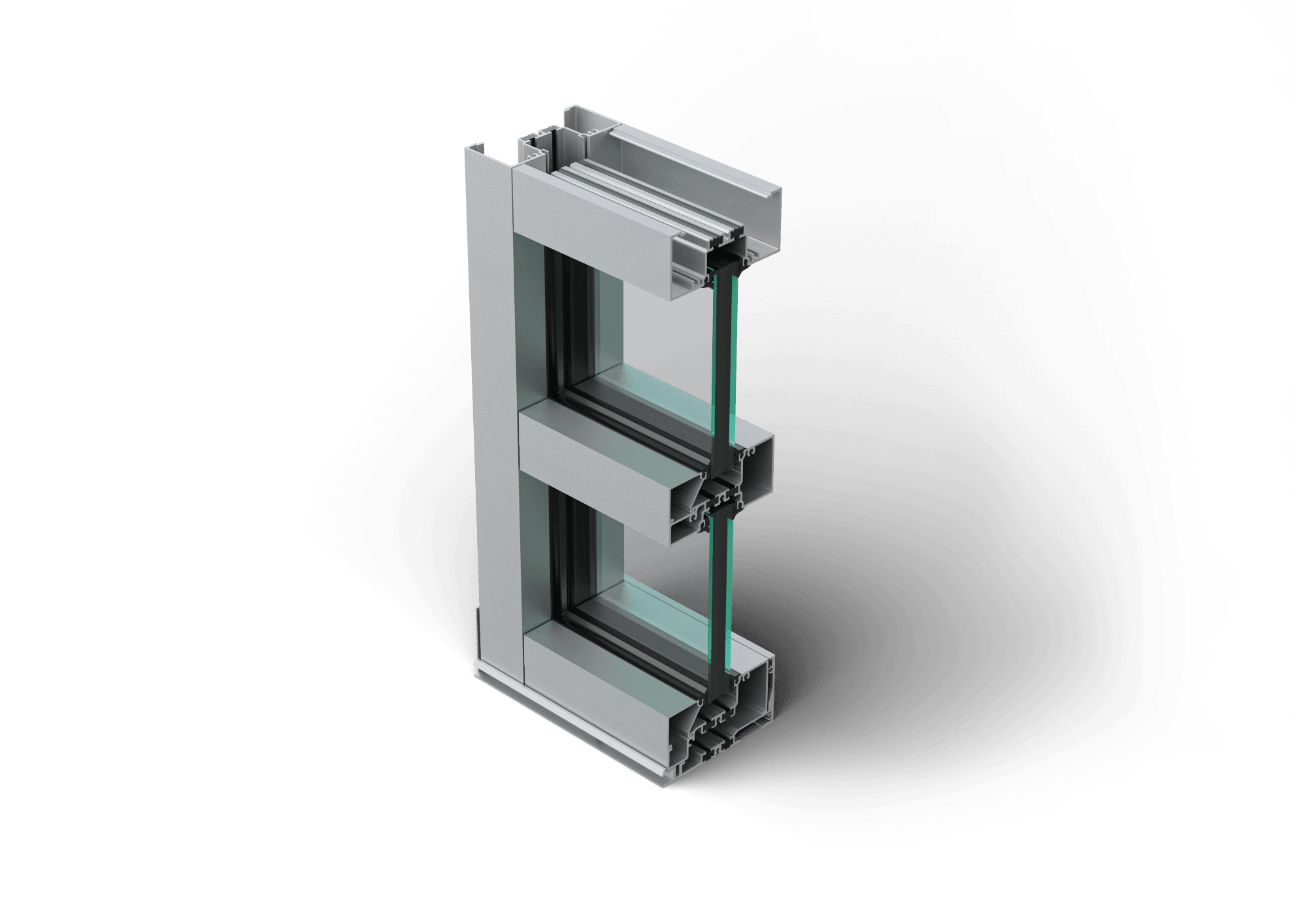

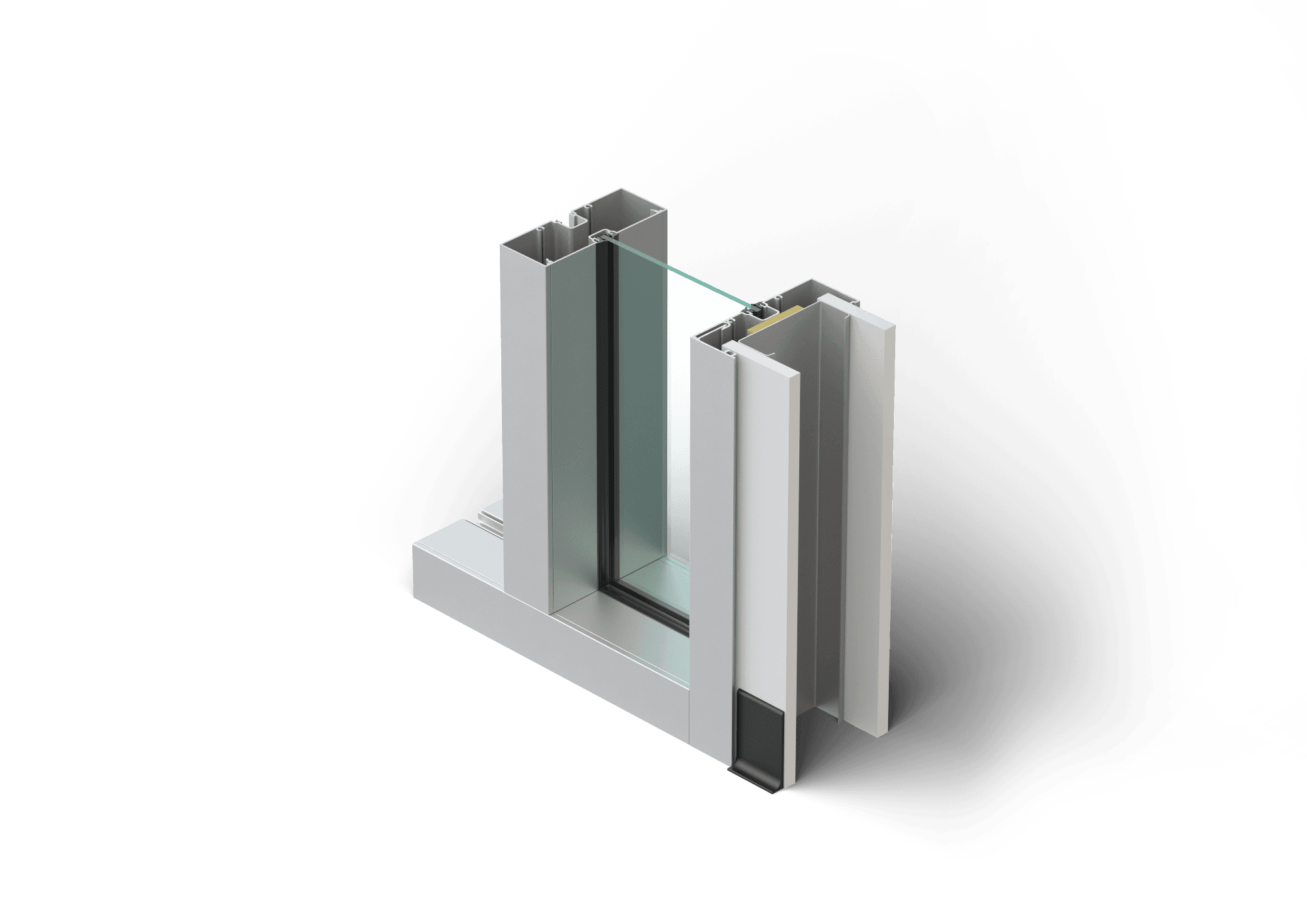

- Applications de verre à plan central

- Éléments de cadre de 1-3/4 po x 4 po (44,5 mm x 101,6 mm) et accepte les remplissages de 1/4 po (6,4 mm)

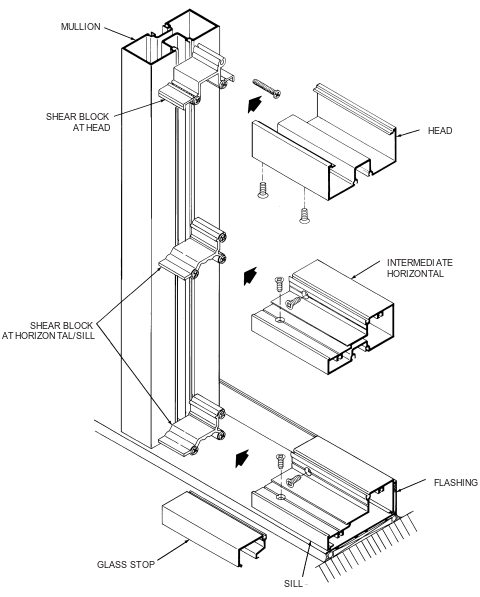

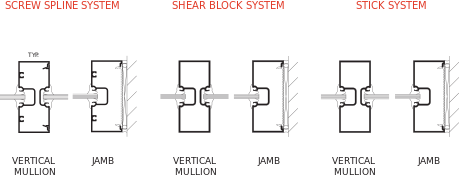

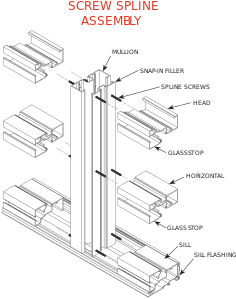

- Choix de construction à vis et cannelures, bloc de cisaillement ou bâton

- Peut être encastré de l’intérieur ou de l’extérieur

Technologie thermique

En savoir plus ici.

Trifab® 400 Framing System - Architectural Detail Manual

1 Mo

Système de cadres Trifab® 400 -

1 Mo

Trifab® 400 Framing System - Product Green Guide

162 Ko

Trifab® Framing Systems and Storefront Framing Systems - EPD

1 Mo

Finishes Information - Architectural Detail Manual

238 Ko

Anodize Finishes - Color Chart

82 Ko

Liquid Paint - Color Chart - Permadize®

1 Mo

Liquid Paint - Color Chart - Permafluor®

350 Ko

Powder Paint - Color Charts - Permacoat®

Trifab® 400 Framing System - English

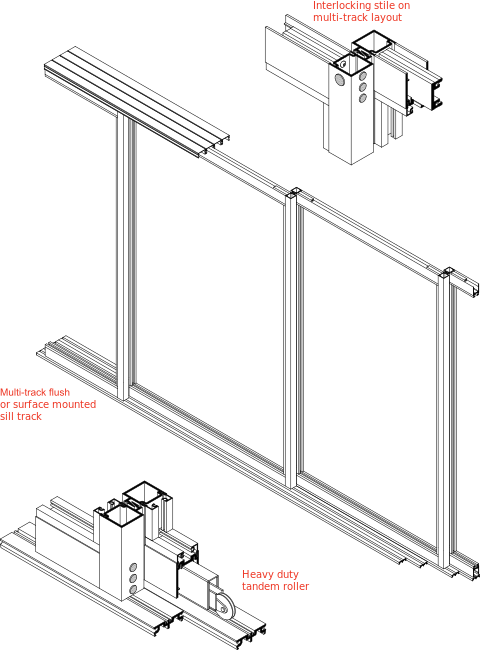

Screw Spline Assembly (Inside Glazed)

Shear Block Assembly (Inside Glazed)

Stick Assembly (Inside Glazed)

GLASSvent® (project out) Details

Entrance Details (Offset Pivot/Butt Hung w/Surface or Concealed Closer)

Entrance Details (Center Hung with Concealed Closer)

Entrance Details - Open Back Frame (Offset Pivot/Butt Hung w/Surface or Concealed Closer)

Entrance Details - Open Back Frame (Center Hung with Concealed Closer)

While most of our products are not hazardous in and amongst themselves, hazardous properties can develop when the product is altered through cutting, welding, and grinding. Details on the specific hazards that can develop and the proper protective measures to use can be found in the SDSs.

Arconic’s SDS database provides PDF files of safety information on specific materials. The SDS ID numbers (product code) and description for materials used in Kawneer products are listed below.

SDS # DESCRIPTION / TITLE

1405 – Kawneer Thermal Break Filled Extrusions

1385 – Kawneer Acrylic Paints

1386 – Kawneer Fluoropolymer Paints

1526 – Kawneer Bloomsburg Solvent Recovery Still Residuals

1387 – Painted Architectural Aluminum Extrusions

509 – Aluminum Extrusions, Anodized Aluminum Products

Search Arconic’s SDS database for safety information on specific materials.

Search Instructions

Project Warranty Cover Sheet (English)

137 Ko

Project Warranty Cover Sheet (French-Canadian)

137 Ko

Project Warranty Cover Sheet Sample (English)

139 Ko

Project Warranty Cover Sheet Sample (French-Canadian)

140 Ko

Material & Workmanship - English

185 Ko

Material & Workmanship - French

190 Ko

Material & Workmanship Sample (English)

203 Ko

Material & Workmanship Sample (French Canadian)

212 Ko

Anodized Finishes Warranty - English

523 Ko

Anodized Finishes Warranty - French

517 Ko

Anodized Finishes Sample (English)

529 Ko

Anodized Finishes Sample (French Canadian)

524 Ko

Painted Finishes Warranty - English

557 Ko

Painted Finishes Warranty - French

538 Ko

Painted Finishes Sample (English)

565 Ko

Painted Finishes Sample (French Canadian)

550 Ko

Insulating Glass Warranty - English

498 Ko

Insulating Glass Warranty - French

499 Ko

Insulating Glass Sample (English)

502 Ko

Insulating Glass Sample (French Canadian)

504 Ko

Laminated Glass Warranty - English

122 Ko

Laminated Glass Warranty - French

123 Ko

Laminated Glass Sample (English)

126 Ko

Laminated Glass Sample (French Canadian)

128 Ko

Corrective Field Repairs (English)

154 Ko

Corrective Field Repairs (French-Canadian)

152 Ko