- Multiple thermal-performance levels resulting from a combination of:

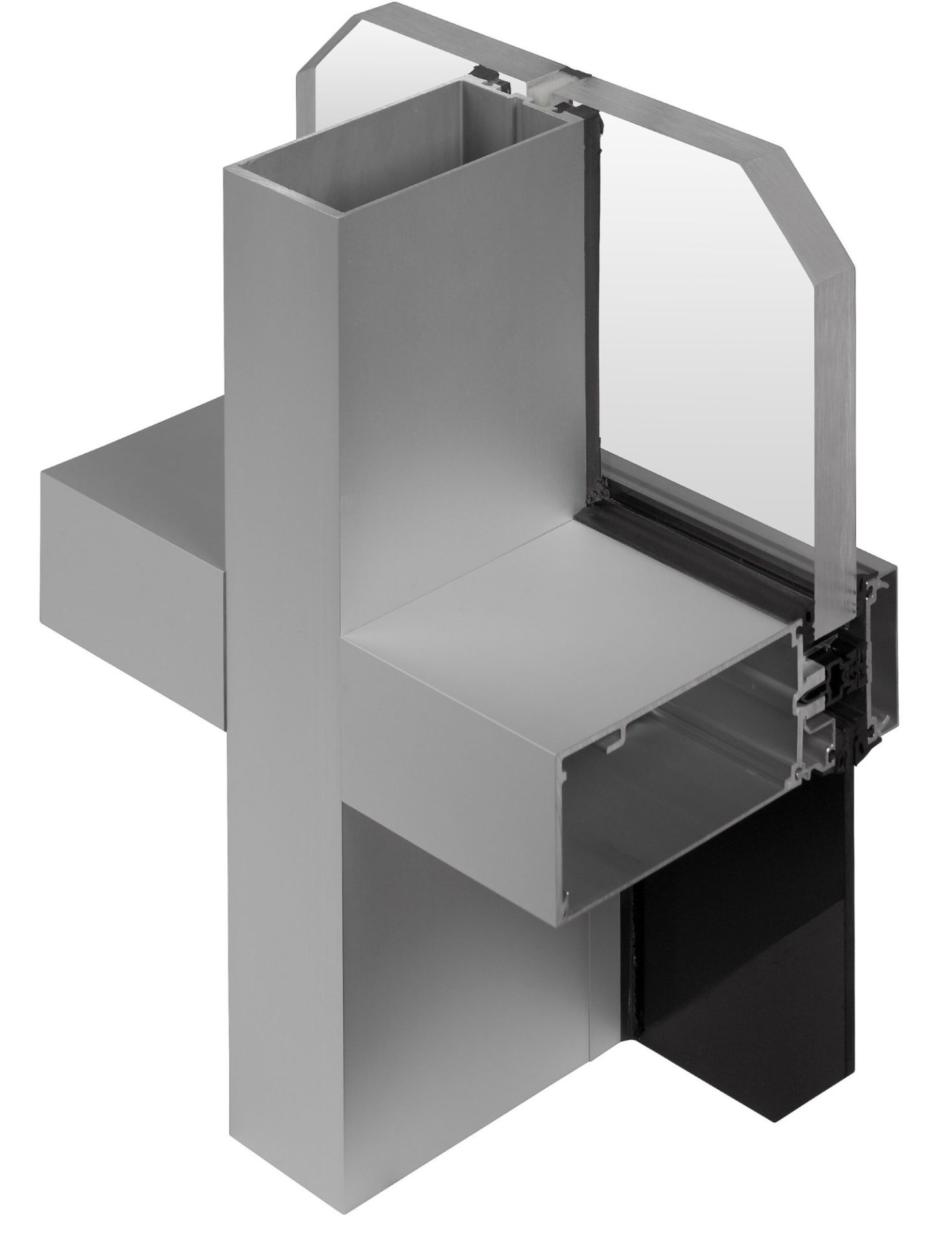

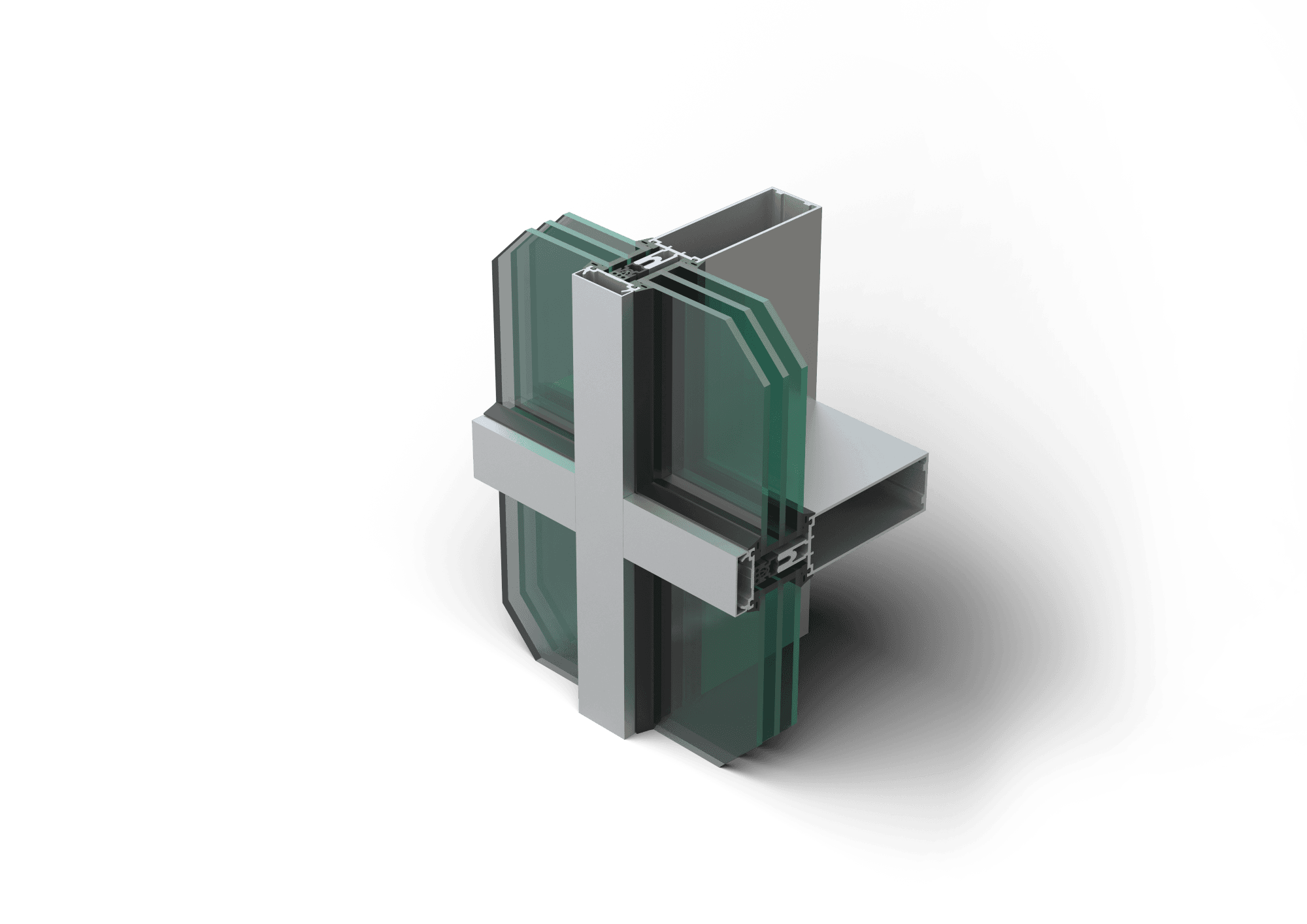

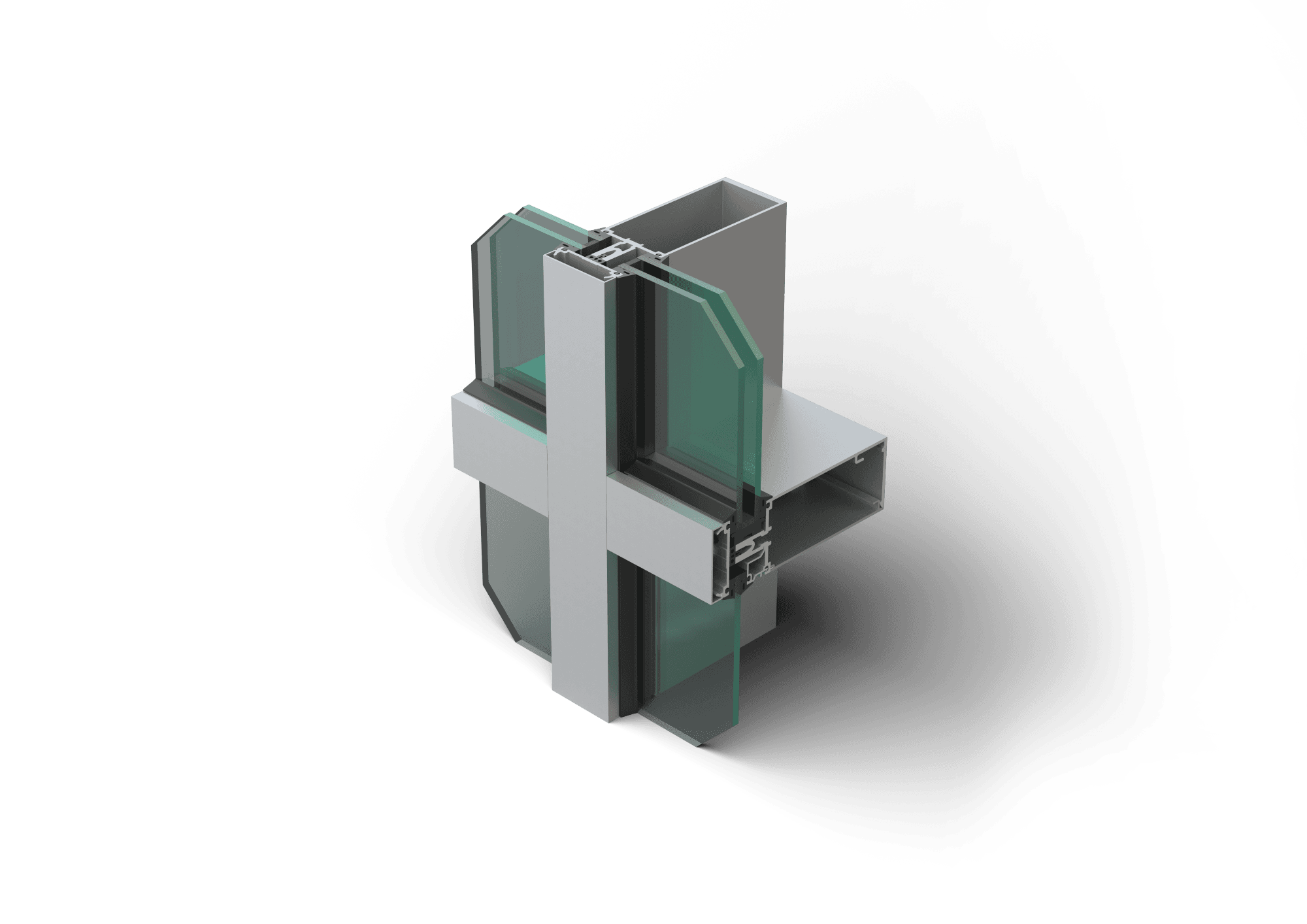

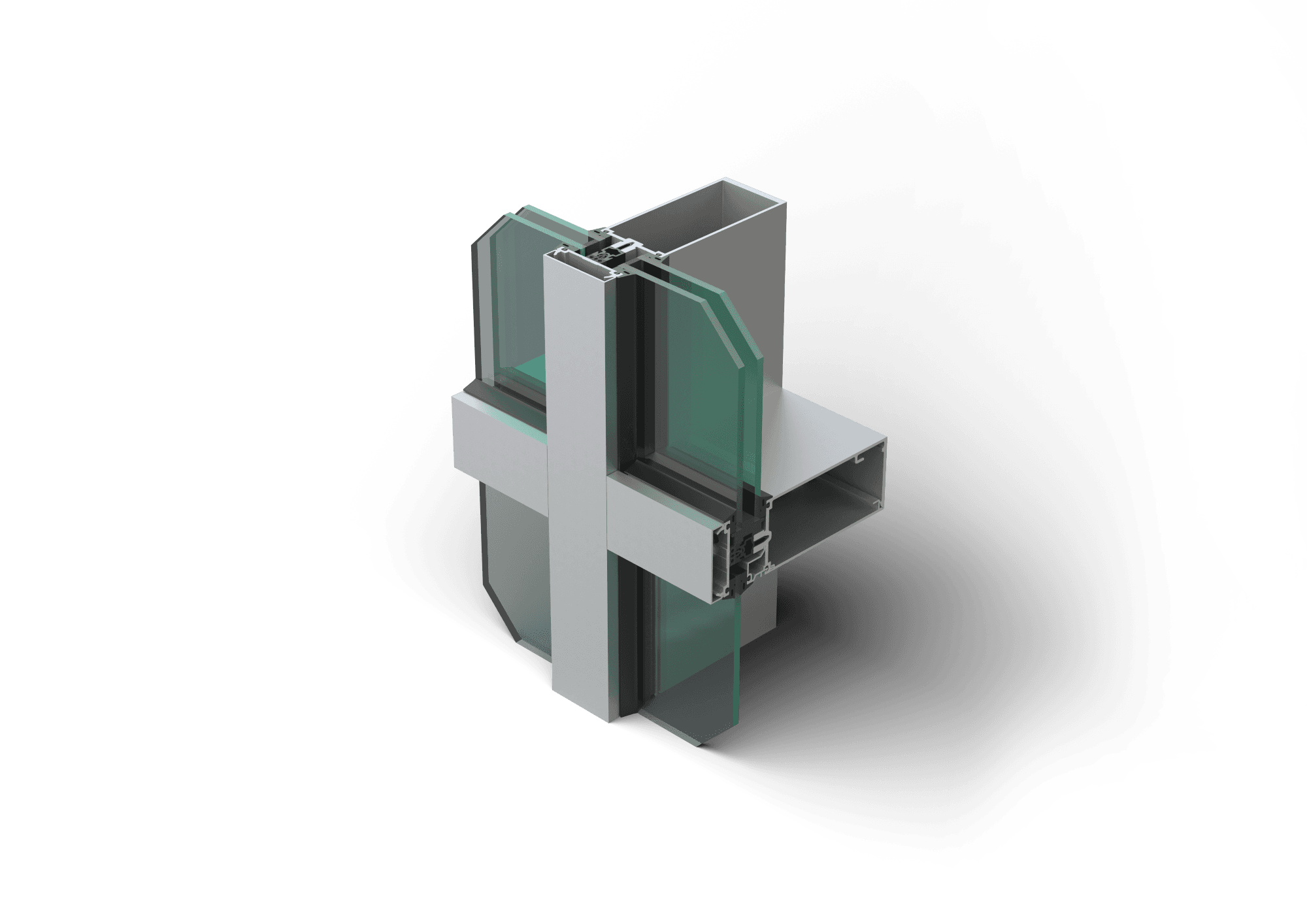

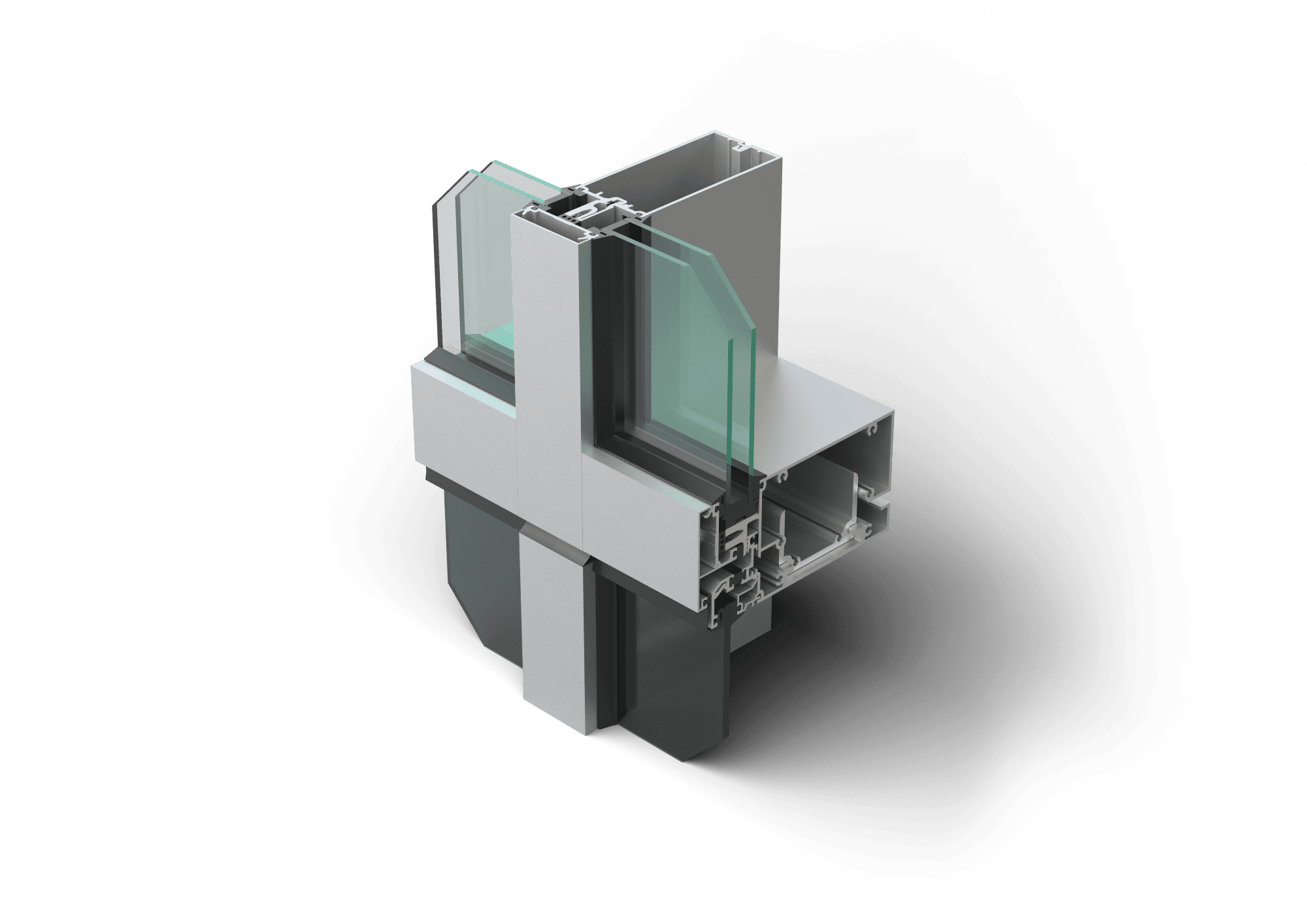

- 1″ (25.4mm) double or 1-3/4″ (44.45mm) triple-pane insulating glass units

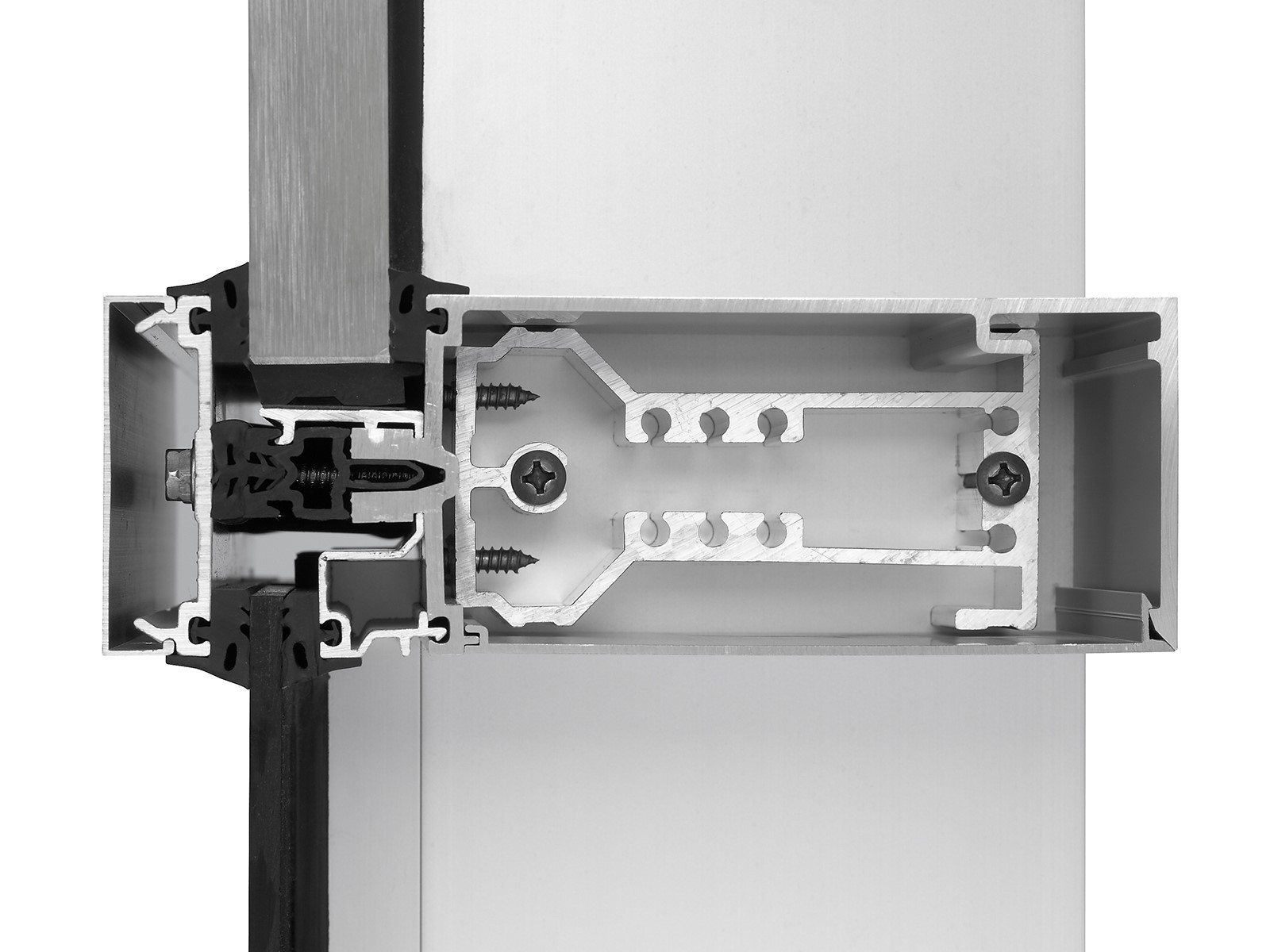

- Aluminum or fiberglass pressure plates

- Thermal barrier design ensures high thermal performance without being susceptible to thermal fatigue

- Offers seamless integration with high-performance or standard entrances and window systems

- Corners and splays available

- Comprehensively tested to latest high-performance air, water, structural and thermal standards

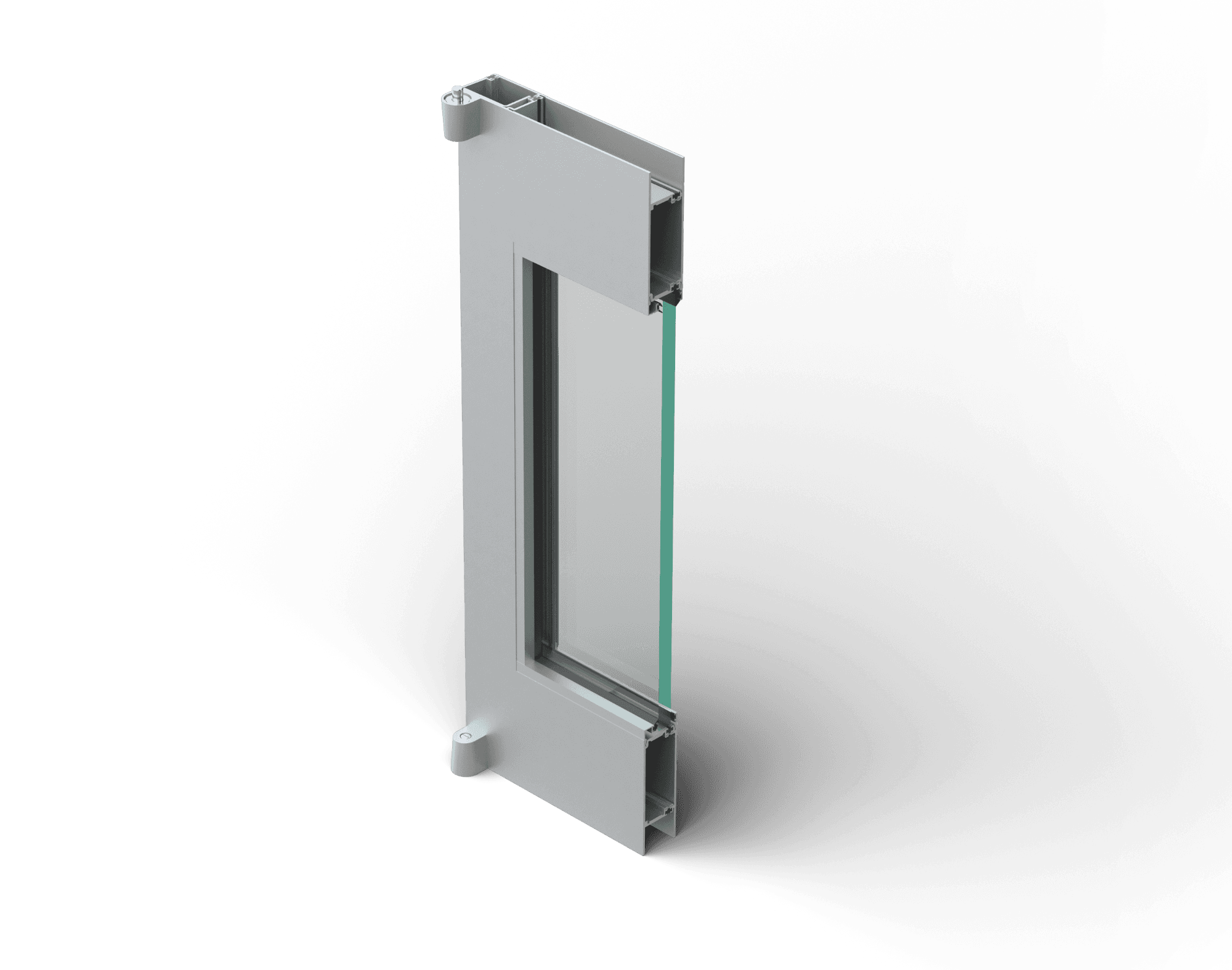

- Glass chairs support insulating glass units, enabling larger expanses of glass

- Pressure equalized system tested with vapor barrier

Optional Features

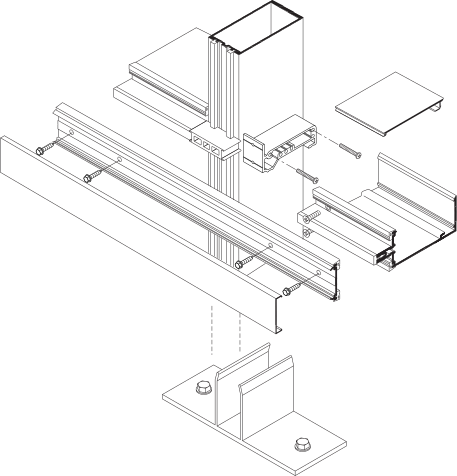

- Steel reinforcing

- Rain screen and backpans

- Deep profile covers and bull nose covers

- Deep and heavy-weight mullions

- Profit$Maker® Plus die sets

- Dual-color option

Product Applications

- Ideal for low- to mid-rise applications where high thermal performance is desired

- High span applications

- Integrates with Kawneer Entrances, GLASSvent®UT and sun control products

Thermal Technology

Find out more here.

1600UT System™2 Curtain Wall - Architectural Detail Manual

16 MB

Mur-rideau 1600UT System™2 - Manuel de détails architecturaux

16 MB

1600UT System™2 Curtain Wall - Flyer

274 KB

Curtain Wall AAMA 501.6 Seismic Test - Flyer

85 KB

Curtain Wall Product Selection Guide

753 KB

Elevating Facades with Kawneer Curtain Wall Covers

1600UT System™1 & 2 Curtain Wall - Product Green Guide

228 KB

Traditional Curtain Wall/Aluminum Curtain Wall Systems - EPD

617 KB

1600UT System®1 Curtain Wall and 1600UT System®2 Curtain Wall Systems - DECLARE Label

803 KB

1600UT System®1 Curtain Wall and 1600UT System®2 Curtain Wall System - MTS

586 KB

Finishes Information - Architectural Detail Manual

238 KB

Anodize Finishes - Color Chart

82 KB

Liquid Paint - Color Chart - Permadize®

713 KB

Liquid Paint - Color Chart - Permafluor®

350 KB

1600UT System™2 Curtain Wall - English

1600UT System™2 Curtain Wall - French

1600UT System™2 Curtain Wall - Spanish

Typical Details with Perimeter Pressure Plate

Typical Details with Thermal Pocket Filler

90° & 135° Corner Details

GLASSvent™ UT Window Details

Entrance Details - Center Hung with Concealed Closer

Entrance Details - Offset Pivot/Butt Hung with SA COC or Surface Closer

Entrance Details - Offset Pivot/Butt Hung with Surface Closer

Entrance Details - OP/BH with SA COC or Surface Closer-250T Insulpour® Door

Entrance Details - OP/BH with Surface Closer-250T Insulpour® Door

Typical Anchoring & Steel Reinforcing Details

Typical Details with Perimeter Pressure Plate

Typical Details with Thermal Pocket Filler

90° & 135° Corner Details

GLASSvent™ UT Window Integration Details

Entrance Details - Center Hung with Concealed Closer

Entrance Details - Offset Pivot/Butt Hung with SA COC or Surface Closer

Entrance Details - Offset Pivot/Butt Hung with Surface Closer

Entrance Details - OP/BH with SA COC or Surface Closer-250T Insulpour® Door

Entrance Details - OP/BH with Surface Closer-250T Insulpour® Door

Typical Anchoring & Steel Reinforcing Details

Typical Details with Perimeter Pressure Plate

Typical Details with Thermal Pocket Filler

GLASSvent™ UT Window Integration Details

Entrance Details - Center Hung with Concealed Closer

Entrance Details - Offset Pivot/Butt Hung with SA COC or Surface Closer

Entrance Details - Offset Pivot/Butt Hung with Surface Closer

Entrance Details - OP/BH with SA COC or Surface Closer-250T Insulpour® Door

Entrance Details - OP/BH with Surface Closer-250T Insulpour® Door

Typical Anchoring & Steel Reinforcing Details

Backpan Details - 1" Infill

Backpan Details - 1-3/4" Infill

Optional Framing Details - 1" & 1-3/4 Infill

Stool Trim Options - 1" & 1-3/4" Infill

Optional 1-1/4" Infill Details

Optional 1-5/16" Infill Details

Typical Details with Perimeter Pressure Plate

Typical Details with Thermal Pocket Filler

90° & 135° Corner Details

Entrance Details - Center Hung with Concealed Closer

Entrance Details - Offset Pivot/Butt Hung with SA COC or Surface Closer

Entrance Details - Offset Pivot/Butt Hung with Surface Closer

Entrance Details - OP/BH with SA COC or Surface Closer-250T Insulpor® Door

Typical Anchoring & Steel Reinforcing Details

Typical Details with Perimeter Pressure Plate

Typical Details with Thermal Pocket Filler

90° & 135° Corner Details

Entrance Details - Center Hung with Concealed Closer

Entrance Details - Offset Pivot/Butt Hung with SA COC or Surface closer

Entrance Details - Offset Pivot/Butt Hung with Surface Closer

Entrance Details - OP/BH with SA COC or Surface closer-250T Insulpour® Door

Typical Anchoring & Steel Reinforcing Details

Typical Details with Perimeter Pressure Plate

Typical Details with Thermal Pocket Filler

Entrance Details - Center Hung with Concealed Closer

Entrance Details - Offset Pivot/Butt Hung with SA COC or Surface Closer

Entrance Details - Offset Pivot/Butt Hung with Surface Closer

Entrance Details - OP/BH with SA COC or Surface Closer-250T Insulpour® Door

Typical Anchoring & Steel Reinforcing Details

1600UT System™ 2 Curtain Wall

1600UT System™ 2 Curtain Wall

While most of our products are not hazardous in and amongst themselves, hazardous properties can develop when the product is altered through cutting, welding, and grinding. Details on the specific hazards that can develop and the proper protective measures to use can be found in the SDSs.

Arconic’s SDS database provides PDF files of safety information on specific materials. The SDS ID numbers (product code) and description for materials used in Kawneer products are listed below.

SDS # DESCRIPTION / TITLE

1405 – Kawneer Thermal Break Filled Extrusions

1385 – Kawneer Acrylic Paints

1386 – Kawneer Fluoropolymer Paints

1526 – Kawneer Bloomsburg Solvent Recovery Still Residuals

1387 – Painted Architectural Aluminum Extrusions

509 – Aluminum Extrusions, Anodized Aluminum Products

Search Arconic’s SDS database for safety information on specific materials.

Search Instructions

Project Warranty Cover Sheet (English)

137 KB

Project Warranty Cover Sheet (French-Canadian)

137 KB

Project Warranty Cover Sheet Sample (English)

139 KB

Project Warranty Cover Sheet Sample (French-Canadian)

140 KB

Material & Workmanship - English

159 KB

Material & Workmanship - French

166 KB

Material & Workmanship Sample (English)

192 KB

Material & Workmanship Sample (French Canadian)

201 KB

Anodized Finishes Warranty - English

523 KB

Anodized Finishes Warranty - French

517 KB

Anodized Finishes Sample (English)

529 KB

Anodized Finishes Sample (French Canadian)

524 KB

Painted Finishes Warranty - English

557 KB

Painted Finishes Warranty - French

538 KB

Painted Finishes Sample (English)

565 KB

Painted Finishes Sample (French Canadian)

550 KB

Insulating Glass Warranty - English

498 KB

Insulating Glass Warranty - French

499 KB

Insulating Glass Sample (English)

502 KB

Insulating Glass Sample (French Canadian)

504 KB

Laminated Glass Warranty - English

122 KB

Laminated Glass Warranty - French

123 KB

Laminated Glass Sample (English)

126 KB

Laminated Glass Sample (French Canadian)

128 KB

Corrective Field Repairs (English)

154 KB

Corrective Field Repairs (French-Canadian)

152 KB